*1 Based on September 2021 OMRON investigation. Applies to M12 quadruple distance models.

E2EW

Welding Proximity Sensor

Stable detection in lines containing both aluminum and iron

近接感測器 選型工具

只需選擇檢測距離/材料/尺寸等必要條件,即可搜索接近傳感器類型。

更新日期 2021年11月8日

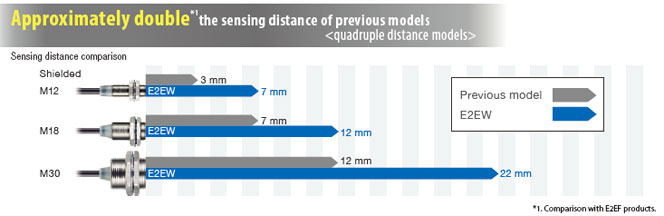

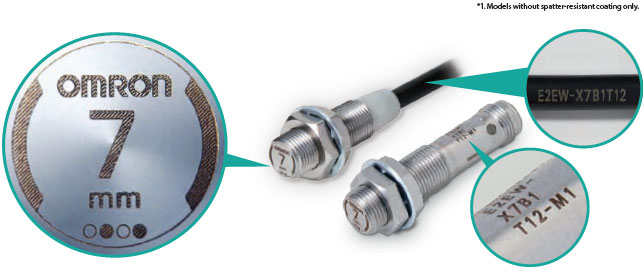

Equivalent sensing distances for iron and aluminum [exceptional sensing range*1 of 7 mm]

Enables facility design with fewer unexpected stoppages even in lines with both iron and aluminum workpieces

Less design work

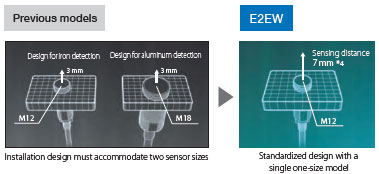

Enables common design for lines with both iron and aluminum

Previously, in order to stably detect sitting in mixed production lines containing both iron and aluminum, facility designs needed to accommodate sensors of different sizes for different sensing distances. With the same sensing distance for iron and aluminum, E2EW Proximity Sensors eliminate the need to change sensors according to workpieces, enabling the standardization of production facilities and mechanical drawings.

*4. Quadruple distance models.

Allows for more spacious sensor installation design

With previous models, to avoid false detections, you were forced to adopt sensor installation designs that risked contact. The E2EW Proximity Sensor, with the exceptional sensing range, can detect accurately from a certain level of distance, which means you can adopt designs with more space to reduce the risk of contact.

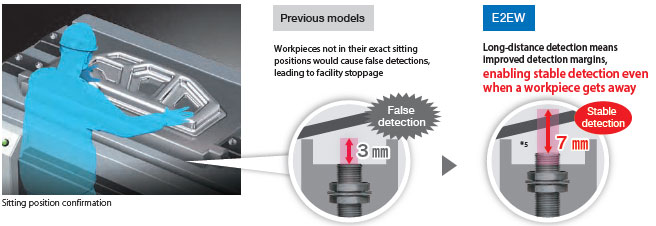

Better operation rates

Reduces unexpected stoppages due to false detections

E2EW Proximity Sensors can detect both iron and aluminum from equally long distances. This longer detection margin means less false detections, even if workpieces are moved from their intended sitting positions. Furthermore, the sensors’ installation distances do not need to be strictly adjusted, making them easy for anyone to install.

*5. Embeddable triple-distance models are also available. Refer to Lineup for details.

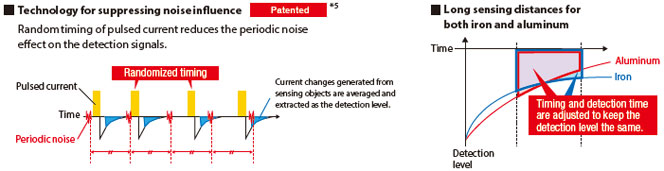

Omron's unique technologies provide equivalent long sensing distances for both iron and aluminum

The problem of previous full-metal body proximity sensors was the short sensing distance. E2EW Proximity Sensors are equipped with Omron's unique technology for suppressing noise influence as well as the PRD*6 technology. The technologies reduce the influence of noise, enabling the extended sensing distance. Furthermore, equivalent long distance detection for iron and aluminum is possible by adjusting the timing and time to detect current changes of sensing objects.

*6. PRD (Pulse Response Detection) is a technology to detect current changes of sensing objects when pulsed currents are applied to coils.

*7. “Patented pending” means that we applied for a patent in Japan, and “Patented” means that we obtained a patent in Japan. (As of November 2020)

Long-lasting spatter resistance eliminates the need to replace for 10 years*1

*1. This value assumes that the sensor operates 10 hours a day in an arc welding environment and is cleaned once a month (12 times a year).

If our previous model (E2EF-Q) needs to be replaced once every 3 times it is cleaned, the E2EW-Q Proximity Sensor needs to be replaced once every 180 times it is cleaned. This means that there is no need to replace the E2EW-Q Proximity Sensor for 10 or more years.

Less frequent maintenance

Spatter resistant fluororesin coating reduces maintenance frequency even in environments with welding spatter.

Less sensor replacements

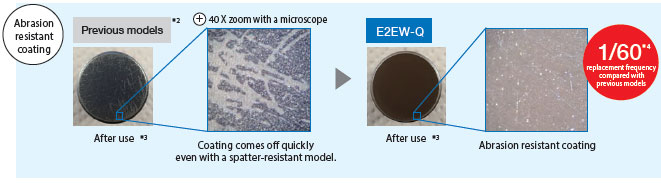

Abrasion resistant fluororesin coating enables long-lasting spatter resistance against cleaning, allowing for less frequent replacement.

*1. Comparison with E2EF-Q products. Based on September 2021 OMRON investigation.

*2. E2EF-Q products.

*3. Brush 10 times vertically and horizontally for each maintenance. Repeat 6 times.

*4. Comparison with E2EF-Q products. Based on September 2021 OMRON investigation.

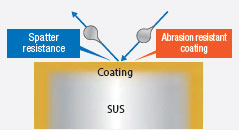

Technologies for increasing spatter resistance [Patent Pending]*5

Key points for increasing spatter resistance:

1. Prevent spatter from sticking

2. Prevent the coating from being worn away during spatter cleanup

OMRON pursued two technologies shown below to deliver long-lasting resistance.

*5. “Patented pending” means that we applied for a patent in Japan, and “Patented” means that we obtained a patent in Japan. (As of November 2020)

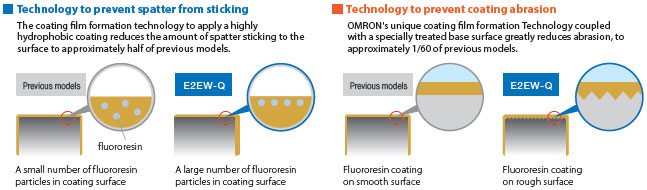

Durable full metal body to reduce unexpected stoppages

Resistance to friction /collisions with workpieces delivers long service life

Thick metal head structure

Resistant to friction with workpieces and metal cleaning brushes

In wear resistance tests using stainless-steel brushes rotating at 130 rpm, insulation breakdown occurred in 50 minutes for resin heads, while no insulation breakdown occurred even after 400 minutes for metal heads.

*Tests performed on an M18 quadruple distance model (with 0.4 mm sensing surface thickness).

Detection level and temperature visualization With IO-Link

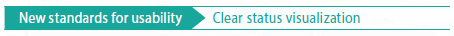

Sensor failures can be detected in 3-wire 2-output (NO+NC) models as well

Enables failure discovery by wiring two outputs, NO and NC

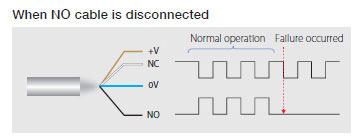

Detection level visualization

A real-time view of how the proximity sensors are detecting objects provides understanding of everyday changes in facility conditions that may not be visible to the naked eye.

*PREMIUM Models only

Application example: Maintenance management based on spatter accumulation

Weld spatter can cause proximity sensors to malfunction. Monitoring detection level changes can allow for timely maintenance.

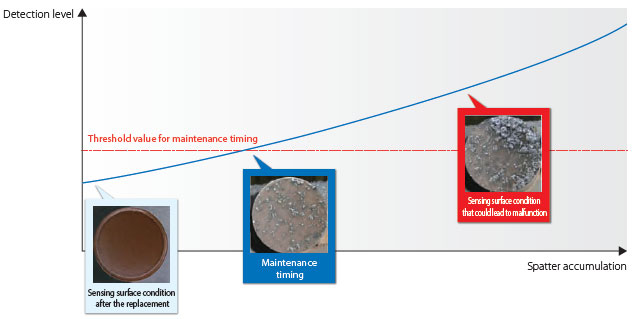

Temperature visualization

Temperature changes in tough environments are visualized in real time, enabling detection of facility malfunction.

Application example: Identifying temperature changes during welding

Proximity sensors installed in multiple sites provide understanding of temperature changes in different locations.

All-around detection status visibility High-brightness LED indicators

Other excellent usability reduces maintenance work

Laser printed information to prevent replacement errors

Laser printed information (sensing distance on the sensor head*1, model on the cable, and model on the metal part of the connector model) can withstand long-term use and be seen clearly, reducing errors during sensor replacement.

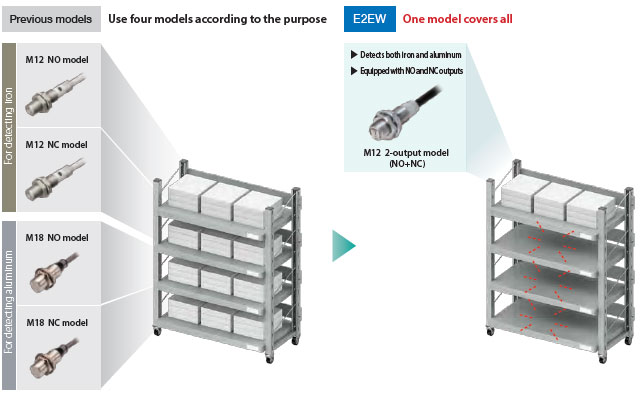

Simplify your inventory to a single model

A customer may currently stock, for example, a total of four models: M12 and M18 models for iron and aluminum, and NO and NC output types for each. The customer now has the option of simplifying their inventory to a single model, the NO+NC 2-output M12 model of the E2EW Proximity Sensor, which meets all these requirements.

This would significantly streamline inventory management and save a great deal of inventory space.

更新日期 2021年11月8日